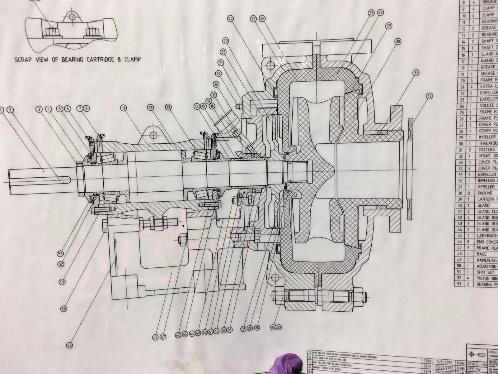

(Dismantle – Fault Find – Refurbish – Rebuild)

Unfortunately, I’d like to start that I have no pictures of the disassembly of the pump.

As we knew the bearing block was fine, it was a matter of urgency that we had it put back in due to the demand the GAC had. The pump was taken apart because it wasn’t operational. When it was taken apart, there was significant pitting on the impeller and the rubber liner, so we ordered new parts.

Bearing Block maintenance

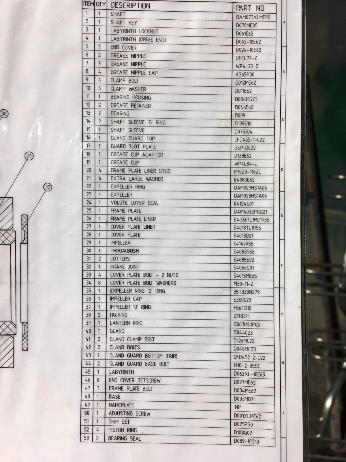

1. Next, I removed the end caps from the bearing block and removed the shim sets as they were worn and we thought it best to replace with new ones.

2. After this, I attempted to replace the shim sets, before realising that we did not have the correct shim sets available to us on site. We ordered in the correct shim set so that the rebuild could be completed.

3. Because we could not proceed no further with the rebuild we dismantled the bearing block and cleaned using the parts washer accordingly.

Bearing Block rebuild

4. The shim kits arrived.

5. We had to put the shim kit back onto the ends of the bearing block. These act as thin plastic gaskets that compress the bearing to the correct depth, whilst ensuring that you can still turn the shaft.

6. A red shim was placed on one end. I put the red shim in its place on the end cap, lined up the bolt holes and then pushed it along the shaft until it met the bearing casing, and then used a rubber mallet to push the end cap with the shim on it up close to the bearing casing.

7. I then placed the labyrinth locknut over the shaft, in front of the end cover and turned it around its thread until it held the end cover in place securely. In order to tighten the labyrinth lock nut properly, I had to use a pipe wrench in order to turn the lock nut on its thread once it started to tighten up (once it got close to the end cover).

8. The labyrinth end cap was then bolted in and before doing so the bolts were wire brushed and copper greased beforehand.

9. I could then start on the shim set on the opposite side of the bearing block. I began by sliding an O-ring over the shaft to sit in its place at the base of the shaft, right up against the bearing housing.

10. Then carried the Bearing Block over where the GAC Sand Transfer Pump would be for it to be fitted.

11. To secure the bearing block in place it took 4 bolts, which before fitting were again wire brushed and copper greased so in the future it will be easier to dismantle for future operations.

We pursued with the pump build

12. The next step was to secure the frame plate to the bearing. This was done by first, cleaning the inside of the frame plate with a wire brush. This removes any unwanted particulates. Then, I had to lift the frame plate so that the bolts protruding from the back of the plate went through the bolt holes on the bearing housing case. I then screwed nuts onto the protruding part of the bolts to secure them in place and tightened them.

13. The gland packing and lantern ring was then fitted into the expeller ring.

14. The expeller ring is fitted onto the shaft of the bearing block, inside the frame plate. This is secured by a push fit system where it locks in place when you push it in hard enough.

15. I fitted the expeller onto the expeller ring by sliding it onto the bearing block shaft and pushing it into place.

16. An O-ring is then fitted between the expeller and frame plant liner.

17. The frame plate liner was then fitted into the frame plate.

18. The impeller was then fitted on.

19. The cover plate with a liner inside it was then fitted. The inner liner and outer liner squish together to create a tight seal.

20. The final step that I was a part of was attaching the drain down valve.